Oil and water separators are devices that are designed to remove oil and other hydrocarbons from water, allowing for the safe disposal of both substances. These separators are used in a variety of industries, including manufacturing, automotive repair, and oil and gas exploration. They are critical for protecting the environment, as oil and other pollutants can be harmful to both people and wildlife.

They work by using gravity to separate the two substances. The process begins by collecting a mixture of oil and water in a container, which allows for the two substances to settle. The oil will naturally rise to the top, while the water will sink to the bottom. Once the separation has occurred, the oil can be skimmed off the surface of the water and disposed of properly, while the water can be safely released back into the environment.

Choosing a precast oil and water separator can offer several benefits over other types of separators. Precast oil and water separators are pre-manufactured in a factory and transported to the site, which means that they can be installed quickly and easily with minimal disruption to the surrounding environment. This means they are:

- Customizable: Precast oil and water separators can be custom-designed to meet the specific needs of the site, such as size, flow rate, and separation efficiency. This means that they can be tailored to suit the unique requirements of each project, making them a more efficient and cost-effective solution.

- High-Quality Materials: Precast oil and water separators are made from high-quality materials, which are durable and resistant to corrosion. This ensures that the separator will last for many years without requiring significant maintenance or repairs.

- Easy to Install: Precast oil and water separators can be delivered to the site and installed quickly. This reduces the amount of time and labor required for installation, which can save businesses money in terms of labor costs and lost productivity.

- Environmentally-Friendly: They are designed to protect the environment by removing oil and other pollutants from water before it is released into the environment. This helps to ensure that water sources remain clean and healthy for people and wildlife.

- Cost-Effective: Since they require minimal maintenance and can be designed to suit the specific needs of the site. Additionally, precast separators can be manufactured in large quantities, which can reduce the overall cost of the project.

We take it a step further by using CarbonCure.

Precast oil and water separators using CarbonCure technology offer additional benefits to traditional precast separators. CarbonCure is a technology that injects waste carbon dioxide (CO2) into the concrete mixture during the manufacturing process, which reacts with the calcium ions in the cement to form a solid mineral called calcium carbonate. This process not only reduces the carbon footprint of the manufacturing process, but also improves the strength and durability of the concrete.

Some benefits of using precast oil and water separators with CarbonCure technology include:

- Reduced Carbon Footprint: CarbonCure technology reduces the carbon footprint of the manufacturing process by injecting waste CO2 into the concrete mixture. This process sequesters CO2 into the concrete, which reduces the amount of greenhouse gas emissions released into the atmosphere.

- Improved Concrete Strength: CarbonCure technology improves the strength and durability of the concrete used to manufacture the precast oil and water separators. This means that the separators can withstand harsh environments and heavy usage, which reduces the need for maintenance and repairs.

- Lower Costs: Precast oil and water separators using CarbonCure technology can be manufactured at a lower cost compared to traditional precast separators. This is because the process of injecting CO2 into the concrete mixture is relatively inexpensive, and the improved strength and durability of the concrete can reduce the need for repairs and replacement over time.

- Enhanced Environmental Benefits: By using CarbonCure technology, precast oil and water separators not only remove oil and other pollutants from water, but also help to reduce greenhouse gas emissions. This provides enhanced environmental benefits, making the use of precast oil and water separators with CarbonCure technology a more sustainable option.

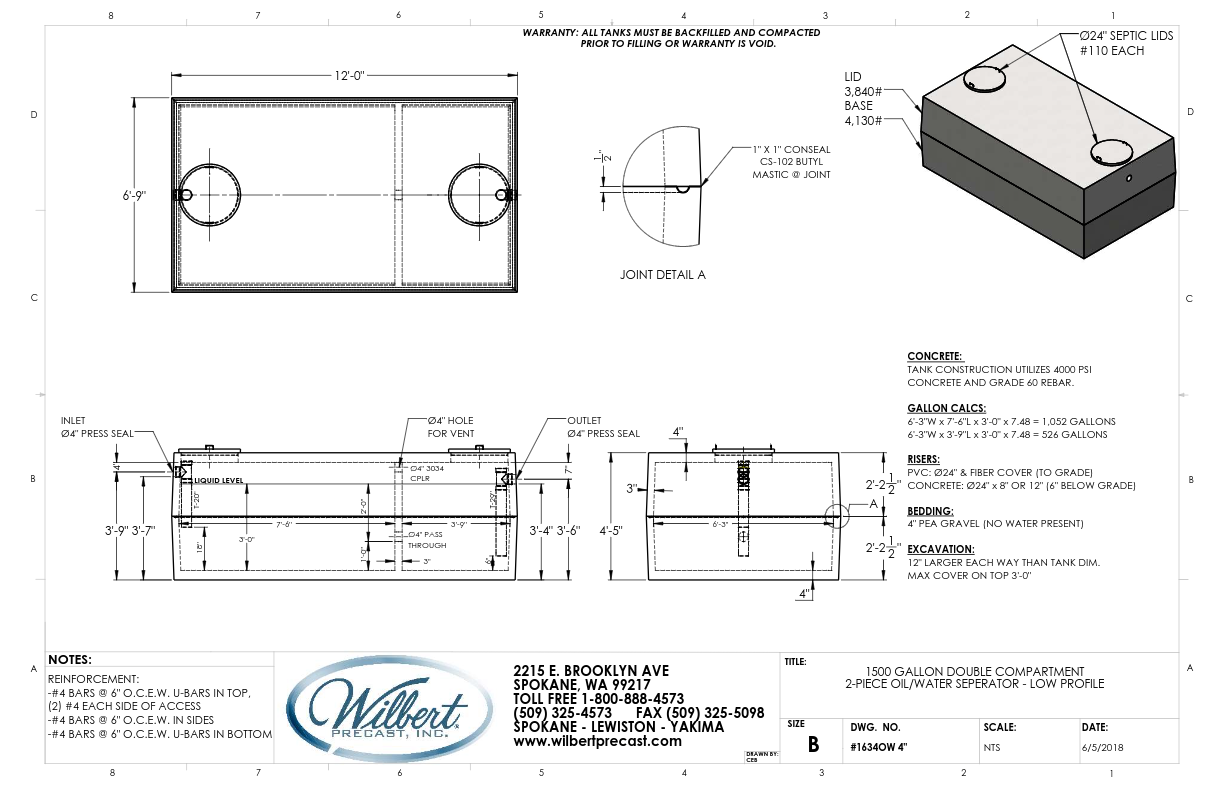

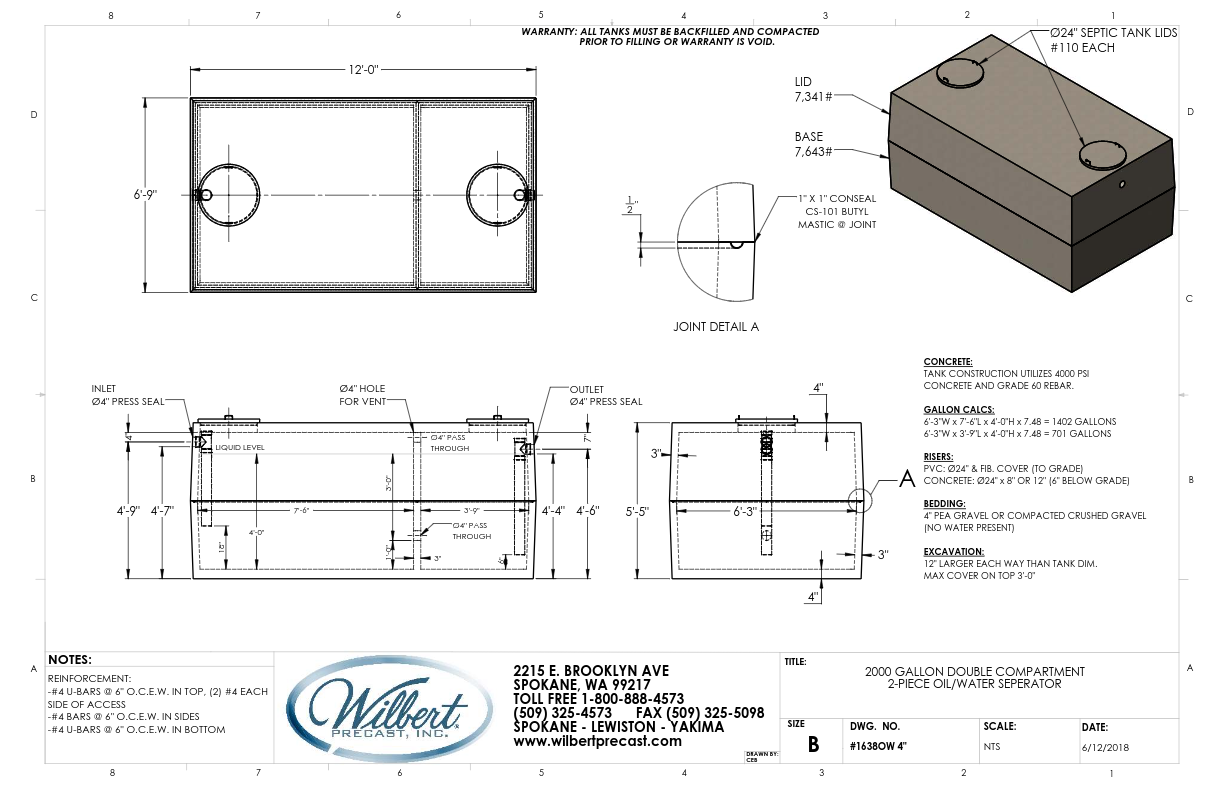

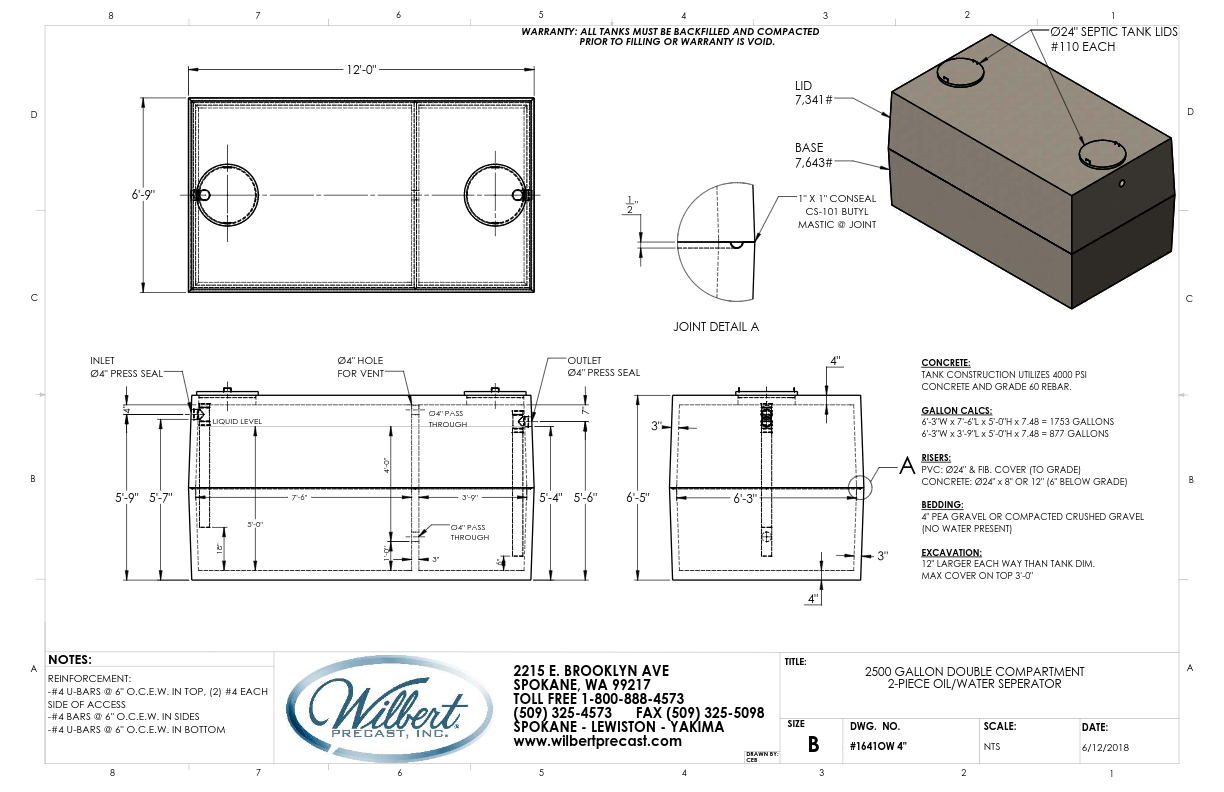

Download the drawings below to see more details about our Oil & Water Separators.

Product ID: 1627MOW

Product ID Double: 1627MOWTB

Product ID: 1634OW

Product ID Double: 1634OWTB

Product ID: 1638OW

Product ID Double: 1638OWTB

Product ID: 1641OW

Product ID Double: 1641OWTB